Recently, while visiting the

Brooklyn Machine Works shop, I had a look at a variety of Laser cut dropouts. I can't get into detail about the the designs I saw there, because I don't have pictures to illustrate them, and there was just

TOO much awesomeness going on there to be described in one post.

Laser Cutting is the general technology used to churn out dropout after dropout for the majority of today's track and BMX frames. Obvious exceptions to this are the forged and machined examples found on some high end bicycles. For the most part however, the single thickness dropouts found on your track bike, were cut with a CNC driven laser.

Plasma cutting is another viable option, and may have been used in the past. However, the width of beam is slightly larger than with a laser, and therefore accuracy is less. With the ever decreasing price of laser cutting technology, its almost easy for designers to get carried away.

(BMW actually doesn't do any laser cutting in house. They do their designs in AutoCAD and contract another metal shop to do that)

I'm not going to

name names, but here we have excessive laser cutting. Its as though the designer wanted some swoopy crescents to dress up his dropouts. A napkin was marked up with a fine tipped sharpie, and sent overseas. The factory reviewed said napkin, said "Sure thing chief!" and away they went with the CAM program. Never mind that the actual crescent shapes have no flow, and subsequently do nothing to create an air of classiness. Now, I don't personally know how much this will affect the strength of the design. I just get this vibe that its a bad idea.

A city ridden bicycle is subject to stresses many times greater than the riders weight when road imperfections are encountered. The axle pushes UP on the dropout with ridiculous amounts of force. These stresses occur at high frequency, every ride. These are the sort of forces that (over time) lead to dropout weldment failures, or similarly seat stay/seat tube junction failures.

A stress riser is essentially where localized forces can overcome the shear strength of a material. And nothing localizes forces more than sharp angles. The stress concentration factor goes up exponentially as the radius of a cut approaches zero. The idea of adding 8 tiny-radius-acute-angle cuts to a small piece of metal that is undergoing high frequency shear forces from the axle just seems like its ASKING to test the elastic modulus of the steel being used.

Just looking at that picture is bothering me enough that I have to model it.

I MUST know just how much these cuts affect the strength of the part!Here I'm starting by importing the photo of the unnamed bicycle dropout into a modeling program, rotating it and scaling it correctly. Then I just draw the existing dropout shape in a 2D sketch:

Now, lets suppress the photo and extrude the basic dropout. Shall we assume it's 5mm thick?

Looks decent.

Okay, here I'm just copying the random swoopy crescent shaped cuts in our unnamed dropout. Looking closely, there is only one straight line. The absolute randomness of these cuts really makes my brow furrow.

...and the final cutout:

Looks horrible doesn't it?

Anyways, on to the testing.

The simplest way to do this, will be to anchor the two faces where the dropout meets the rest of the frame. Next I'm going to put a very slight axle groove in the top of the dropout so that the forces of the axle can REALLY be localized. (as opposed to applying force along the entire upper edge of the dropout) Remember, I'm trying to simulate an axle impacting this thing.

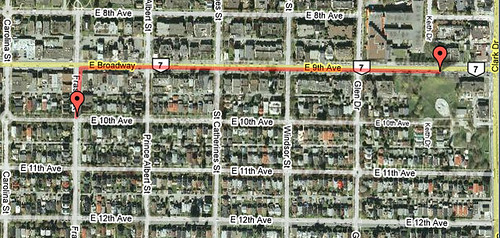

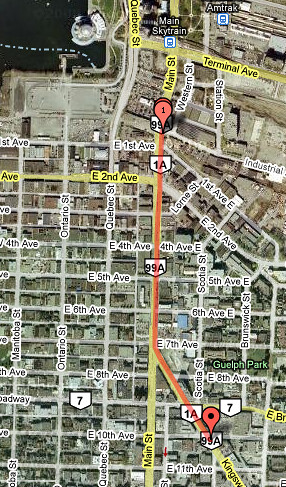

Okay, lets assume our Proj-B test rider weighs about 190lbs. If he hits an object (like a wheel swallowing pothole in the South Bronx) then the force on the axle is going to be several times his mass. We don't actually need to use any particular value here, because I'm going to use the same value to test the dropout with and without the fancy cutouts, but lets assume that the force is twice the rider's weight, thats 1690N being applied at the upper edge of the dropout

This program has a

handy stress analysis tool that allows one to calculate the Factor of Safety (FOS) of a part. Simply put the FOS is the Material's yield strength divided by the equivalent stress at a point.

-An FOS less than 1.0 at a location indicates that the material at that location has yielded.

-An FOS of 1.0 at a location indicates that the material at that location has just started to yield.

-An FOS larger than 1.0 at a location indicates that the material at that location has not yielded.

So, for the Plain old dropout, and a 1690N force, we get a FOS of: 5.25102

No problem. I would ride this all day.

The

Von Mises stress distribution on the model look like this:

Lets repeat that test for the Fancy Cutout version:

Here our FOS is 4.43389 That's 15% less strength!

These pictures show the model in a total deformed state, though thats not actually the case for these applied forces. The dropout will NOT deform under these conditions. The program just uses this to illustrate how the stresses are distributed.So what can we tell from this?Well, its certainly more colourful. You can see where the stress is concentrated in this last picture. That lower crescent and the little arrow head appear to be areas of concern. It seems the cutout dropout is only 85% as strong as the solid one. Whether or not that is 'strong enough' is entirely subjective. Much like my opinion of the aesthetic design of this particular dropout.

I started playing around, finding the maximum force before the material would actually deform. It seems the solid dropout could withstand a force of 9kN or 2020lbs before it would yield.. and even then, just barely:

When that same force is applied to the cutout version, we see a couple more areas of deformation. Most notably is that little pointy arrowhead tip again:

I guess today I've learned that fancy cutouts aren't really as bad as I thought they were. I've also learned how easy it is for me to get sidetracked into theoretical testing and hypothesizing simply by staring at a picture of a bicycle for too long.

If any of this bicycle's designers are reading, please don't feel too slighted by my words. (I didn't even touch upon your

PBR bike!) I am only doing this because I wish i was doing what you are doing.